important information

FOR YOUR HELP

Specifications

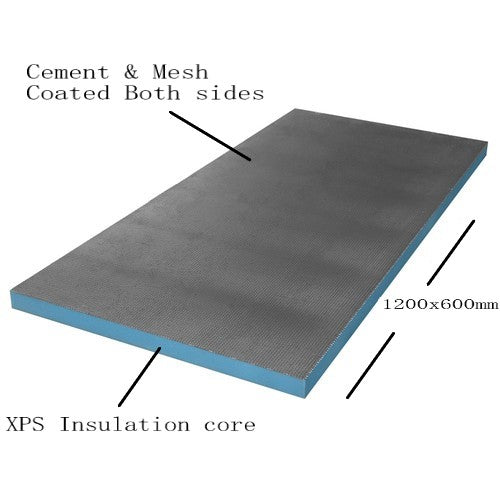

Dimensions: 1200mm × 600mm

Thickness Options: 6mm, 10mm, 12.5mm, 20mm

Core Material: High-density XPS (Extruded Polystyrene)

Surface Finish: Cement-coated with fibre mesh reinforcement

Waterproof: 100% waterproof, mould-resistant

Compressive Strength: High load-bearing capacity of 300 kpa suitable for floors and walls

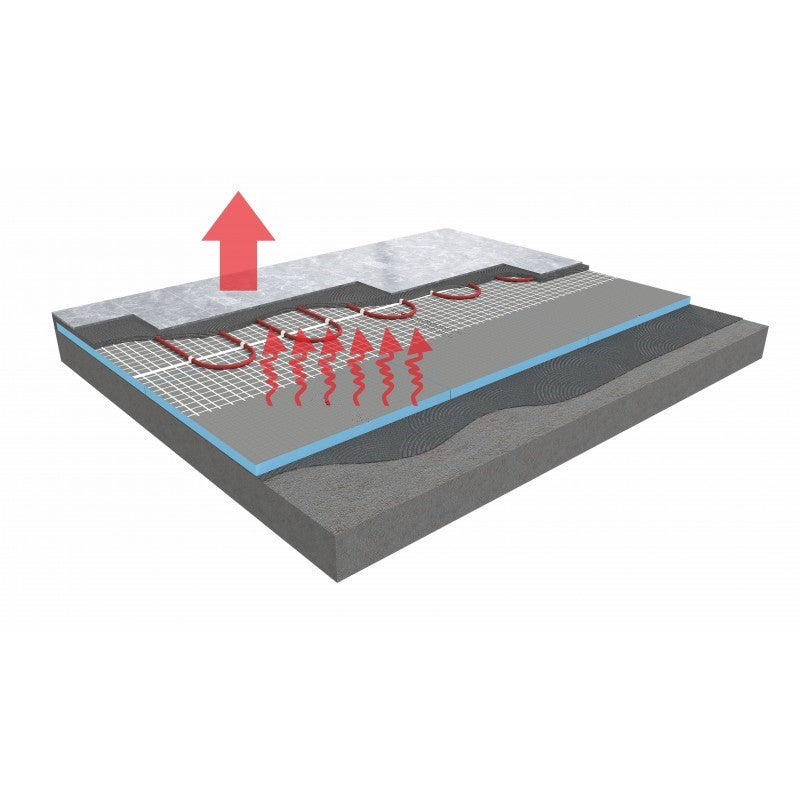

Thermal Insulation: Excellent insulation; ideal for underfloor heating

Sound Insulation: Reduces noise transmission (varies by thickness). For example, a dB value for a 10mm board is more than 20.

Weight: Lightweight (approx. 800g for 10mm board)

Cutting: Easily cut using a utility knife or fine-tooth saw

Eco-Friendly: Manufactured without CFCs

Typical Uses: Bathrooms, wet rooms, kitchens, floors, walls, shower areas, and as a tile substrate

FAQ's

Q1: Can I tile directly onto this board?

Yes. The cement-coated surface provides an excellent key for tile adhesives.

Q2: Are these boards suitable for showers and wet rooms?

Absolutely. They are fully waterproof, rot-proof, and mould-resistant.

Q3: What thickness should I choose?

6mm: Wall linings and levelling surfaces

10–12.5mm: General-purpose use on walls and floors

20mm: Extra insulation or where higher strength is required

Q4: Do I need special tools to cut it?

No. You can simply score and snap with a knife or cut using a saw.

Q5: Can this be used with underfloor heating?

Yes. The XPS core provides thermal insulation and improves heating efficiency.

Q6: Can I install it over uneven surfaces?

Yes, but severe unevenness should be levelled first for best results.

Q7: Do the joints need sealing?

Yes — especially in wet areas. Use waterproof tape or mesh tape over all joints.

Installation Guide

Installation Guide

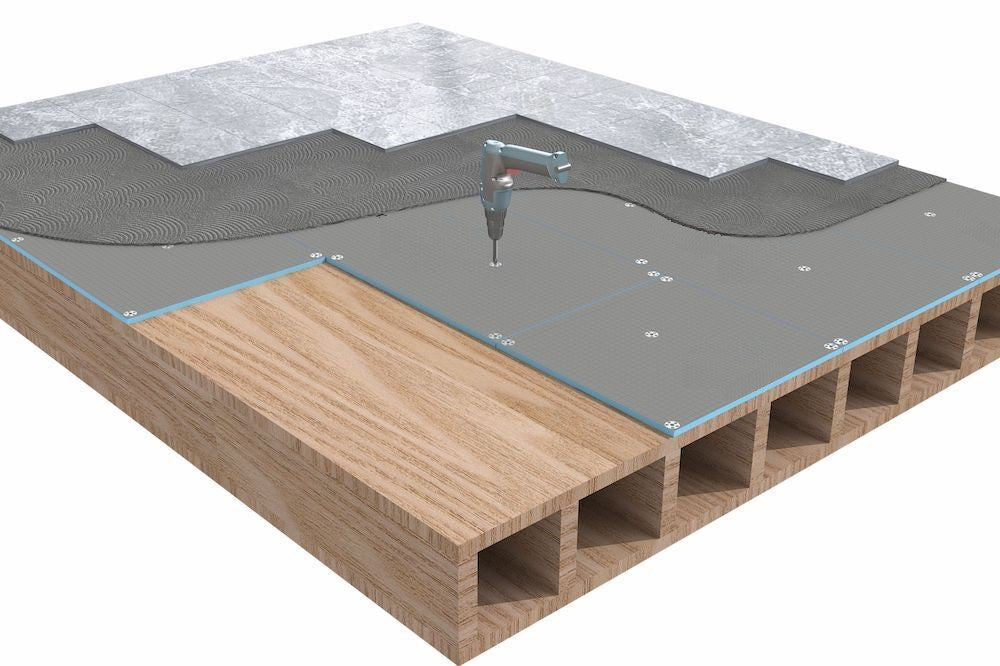

1. Prepare the Surface

- Ensure the surface is clean, dust-free, dry, and level.

- For floors, use a levelling compound if required.

2. Measure & Cut

- Mark the board where needed.

- Score and snap with a utility knife or cut using a saw.

- Boards can be shaped easily around pipes and fixtures.

3. Apply Adhesive

- Floors: Use flexible tile adhesive with a notched trowel.

- Walls: Apply adhesive and secure with screws and washers for additional support.

4. Fix the Boards

- Press boards firmly into the adhesive bed.

- Lay them edge-to-edge with tight joints.

- Stagger the boards where possible for added rigidity.

5. Seal All Joints

- Apply waterproof mesh tape or sealing tape over every joint.

- This step is crucial in bathrooms, showers, and wet-room areas.

6. Finish the Surface

The cement-coated surface is immediately ready for:

Tiling, plastering, rendering, underfloor heating, and installation.