Extruded polystyrene (XPS) insulation boards are a popular choice in modern construction thanks to their high compressive strength, low water absorption, and excellent thermal performance. They are commonly used beneath floors to improve energy efficiency and comfort.

However, the installation method for XPS boards varies significantly depending on whether the subfloor is concrete or timber. Understanding these differences is critical to achieving long-term performance, avoiding moisture issues, and meeting building regulations.

Why Subfloor Type Matters

Concrete and timber subfloors behave very differently:

-

Concrete is rigid, moisture-prone, and dimensionally stable

-

Timber is flexible, breathable, and sensitive to moisture movement

Because of this, XPS installation must be adapted to suit each substrate.

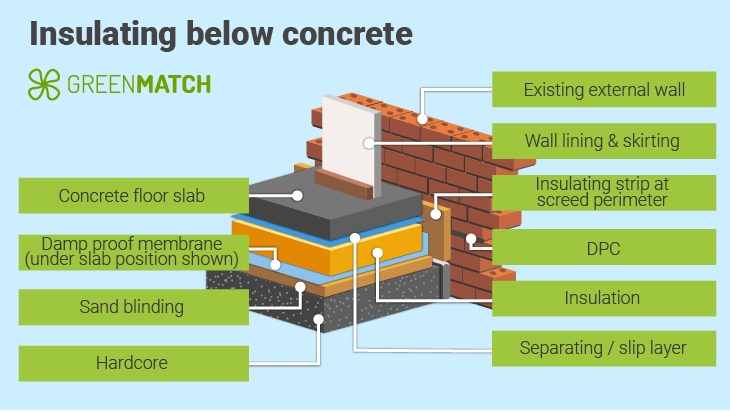

Installing XPS Boards Over Concrete Subfloors

Key Characteristics

Concrete slabs are strong and flat but can transmit ground moisture and feel cold underfoot. XPS boards work exceptionally well here due to their closed-cell structure and high compressive strength.

Installation Method

-

Prepare the slab

Ensure the concrete is clean, dry, and level. Any debris or sharp protrusions should be removed. -

Install a damp-proof membrane (DPM)

A polyethylene DPM is essential unless the slab already incorporates one. This prevents moisture migration into the insulation and floor finishes. -

Lay the XPS boards

Boards are typically laid loose with tightly butted joints. Stagger joints for added stability and reduced thermal bridging. -

Apply a floating layer or screed

-

Floating chipboard, plywood, or OSB panels

-

Or a reinforced sand–cement or liquid screed (often with a separation layer)

-

Advantages

-

Excellent load-bearing performance

-

Strong resistance to moisture

-

Ideal for underfloor heating systems

Challenges

-

Requires careful moisture control

-

Uneven slabs may need levelling compounds

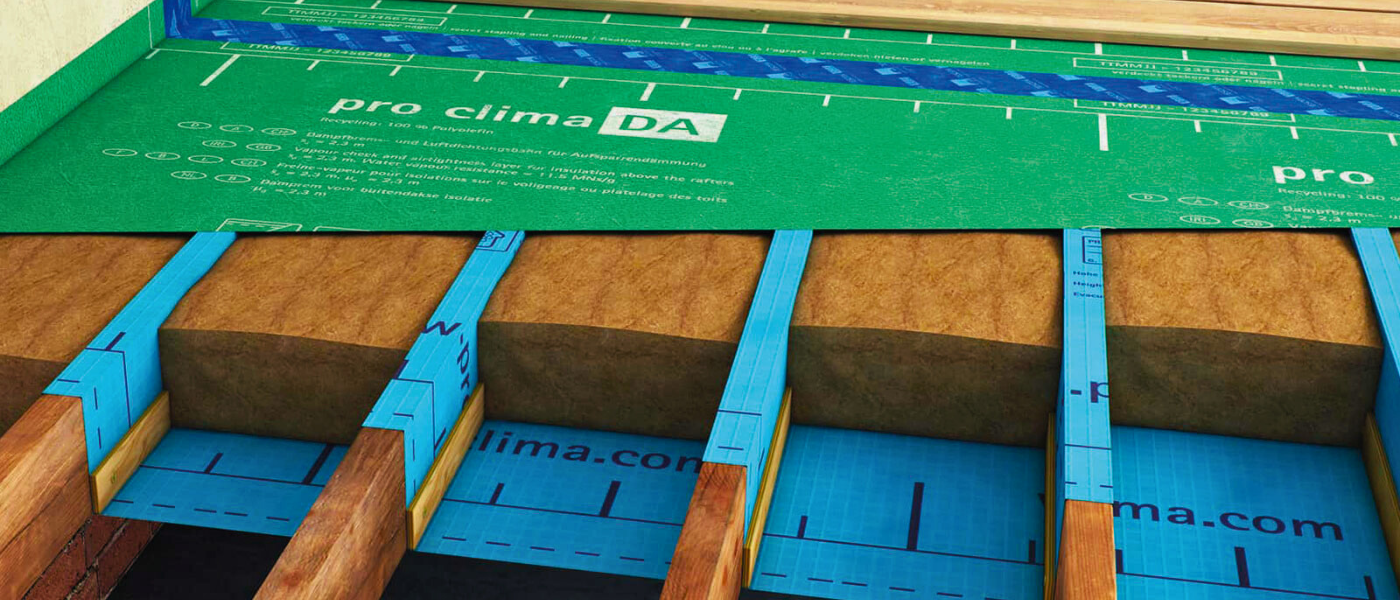

Installing XPS Boards Over Timber Subfloors

Key Characteristics

Timber subfloors are lighter and more flexible than concrete. They expand and contract with changes in temperature and humidity, which influences how rigid insulation should be installed.

Installation Method

-

Assess the timber structure

Check joists and decking for damage, movement, or rot. Structural integrity is critical before adding insulation. -

Install a vapour control layer (VCL)

Unlike concrete floors, timber floors need to manage internal moisture. A VCL helps prevent warm, moist air from condensing within the floor buildup. -

Lay the XPS boards

Boards are usually installed over a continuous timber deck rather than directly on joists. Mechanical fixing or overlay boards may be required to prevent movement. -

Add a structural overlay

A floating floor deck (such as tongue-and-groove chipboard) is installed above the XPS to distribute loads evenly.

Advantages

-

Lightweight solution for suspended floors

-

Improves thermal performance without excessive floor build-up

-

Good compressive strength compared to other rigid insulations

Challenges

-

Reduced breathability compared to mineral-based insulation

-

Risk of trapped moisture if vapour control is poorly designed

-

Movement in timber can cause squeaks or joint stress if not detailed correctly

Concrete vs Timber: Key Differences at a Glance

| Feature | Concrete Subfloor | Timber Subfloor |

|---|---|---|

| Moisture risk | High (ground moisture) | Moderate (internal condensation) |

| Membrane required | Damp-proof membrane (DPM) | Vapour control layer (VCL) |

| Load handling | Excellent | Requires load-spreading layers |

| Installation complexity | Straightforward | More detailing required |

| Suitability for XPS | Excellent | Good with correct design |

Common Mistakes to Avoid

-

Skipping membranes and relying on XPS alone for moisture resistance

-

Installing XPS directly on uneven timber without load distribution

-

Failing to allow for timber movement

-

Not taping or sealing insulation joints

Final Thoughts

XPS boards are a robust and versatile insulation solution, but their performance depends heavily on correct installation. Over concrete subfloors, XPS offers outstanding durability and moisture resistance with relatively simple detailing. Over timber subfloors, success lies in careful moisture management, load distribution, and accommodating structural movement.

Choosing the right installation approach ensures warmer floors, improved energy efficiency, and a longer-lasting build—regardless of what lies beneath your feet.